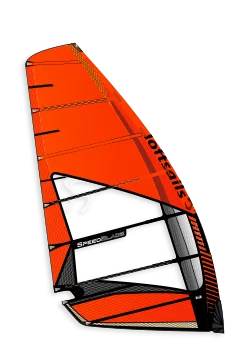

Speedblade 2018

NO-COMPROMISE SPEEDSAILING

Loftsails’ Speed Blades are dedicated speed designs that have consistently broken the “50-knot barrier”. Loftsails Speed Blades won events such as the prestigious Luderitz-Canal challenge in Namibia. Speed Blades are developed with Speedsailing legend Erik Beale, Loftsails’ Speed Team and Speed Product Manager. Similar to Racing Blades in design, Speed Blades are tuned with slightly more upper leech release to suit downwind courses typical of serious speed sailing courses.

Find a dealerFeatures

& Benefits

- Internal vertical and horizontal Kevlar strip applications at cams– defines profile and augments stability

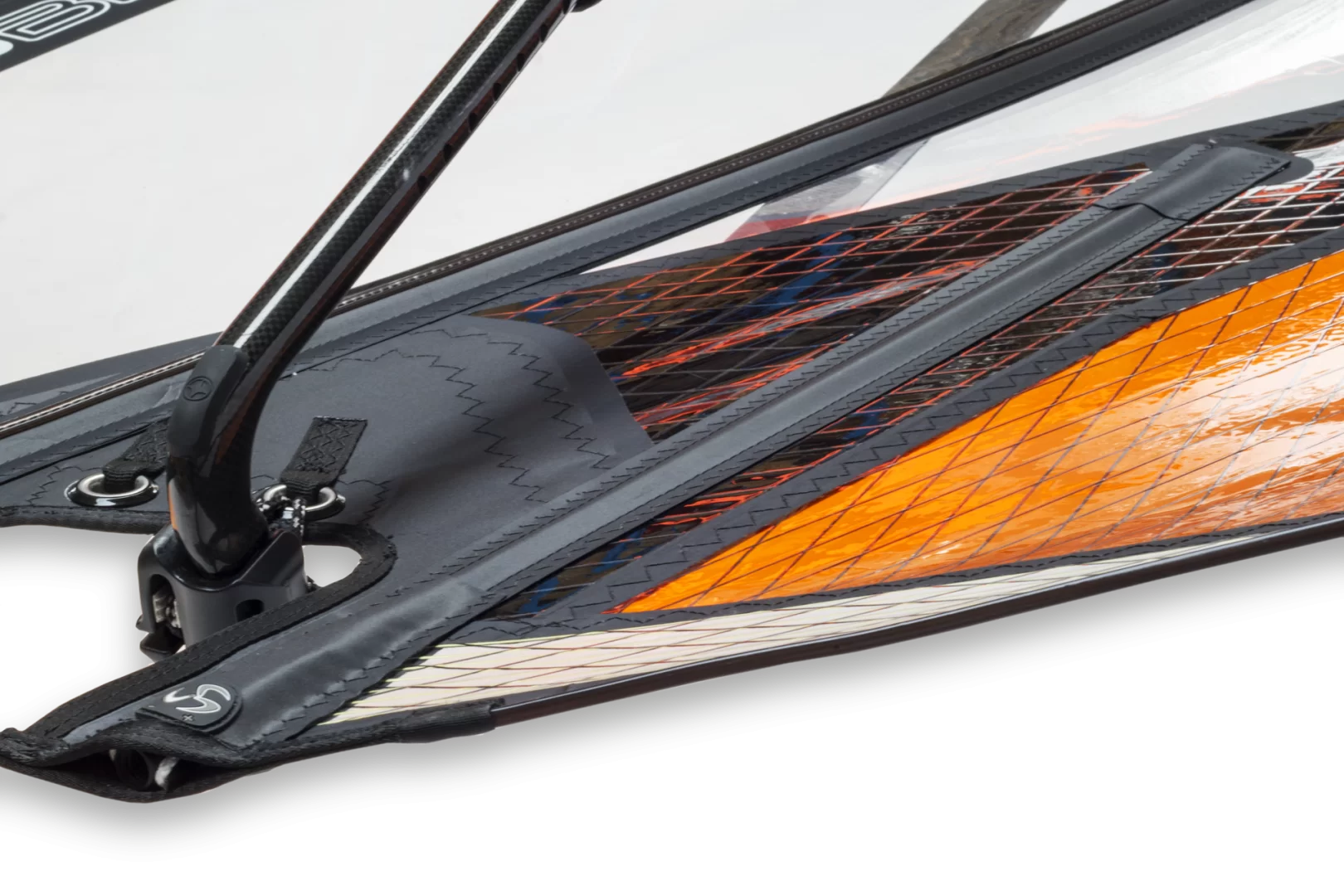

- Blade mast-pocket construction features mast panel and 2 mil triax xply mast-pocket sides (3 layers) that are tensioned directly (all 3 layers under tack pulley webbings)– therefore downhaul tension is equalized between the mast panel and the mast pocket resulting in the Speed Blade’s firm, clean, easy-rotating leading edge

- 4 mil Dimension Polyant monofilm body panels – proven superior performance

- Tubed battens with varying carbon content according to performance. The top 3 are specialized 100% carbon tubes Carbon tubes deliver superior stiffness to maximize stability for your upper end

- Unique Sdm and Rdm mast compatibility. Tekcam2 Large (installed) and Reduced (in sailbag) included with all sizes

- Metallic cam interfaces– MCIs eliminate contact point degradation characteristic of cam designs without MCIs

- Xply batten pockets that alternate sail sides... using similar material for the batten pocket as the body material minimizes the asymmetric character of applied batten pockets. Pockets made with laminates allow the batten to be centered. These features combine to maintain rotation symmetry. In contrast, same-side dacron pockets promote assymetrical rotation.

- Neoprene boom cutout with dual zippers– the rig is streamlined for improved speeds

- RDM/SDM compatible – Both mast types fully compatible to maximize your windsurfing experience

- 7 mil monofilm vertical internal panel (inside mast-pocket)– profile stability

Click to reveal features.

Sail Specifications

Quotes

Frequently asked questions?

Find the answers of your Speedblade 2018 questions

Just click the box below.

I can see minor colour inconsistancy in the coloured monofilm material, is this a quality problem?

Loftsails using high quality Dimension Polyant films considered as a leading film manufacturer. The BI-PLY colored monofilm are two films laminated together. During production there is a large temperature difference between the two films at the lamination point. This causes the top film (film with color adhesive) to slightly shrink and the bottom film does not shrink at the same rate. This can cause "a slight minimal wave or impression" in the fabric. There is no concern on laminate quality.

What does 1 Year Unconditional + 1 Year Conditional warranty cover?

Warranty is valid 2 years after date of purchase. When making a warranty claim in the first year the product is unconditionally warranted. When making a warranty claim in the 2nd year the product must have clearly suffered from a manufacturer error.

When unrolling my sail some battens are looking pre-curved?

All windsurfing sails with battens experience batten bending when rolling for transport. The battens will bend because of the curves cut into the sail to produce profile. Loftsails are rolled right side up, this flexes the battens as if the sail is on starboard tack. Battens are made from polyester, carbon and resin. They remember their being curved, which gives the sail a pre-disposition to be on starboard tack. This results in the sail having a preference to be on starboard tack. This asymmetric character is normally not an issue. Rolling the sail port side up will tend to bend the battens in the opposite direction which can minimize this asymmetric character.

Why are there small wrinkels visible in the footpanel of my sail?

Monty comments: Wrinkles in the foot panel are common to my designs! There is always alot of profile worked into the bottom of the vertical seam, I have tried to remove the wrinkles from the lower panel but this results in flatter shapes that do improve performance. Many of our sails do not show such foot panel wrinkles, however unfortunately one could say they are typical of my designs.